Kog jdd nm nomex sleeving consist of 100 continuous nomex fiber.

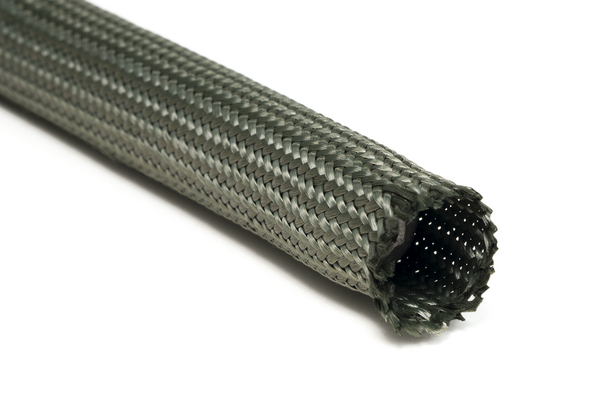

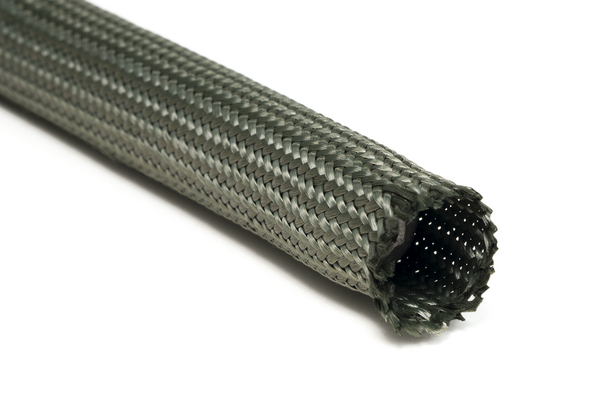

Nomex cable sleeving.

It can retain its integrity at temperatures over 245 or exposed to high humidity moisture or extreme temperature.

Although its soft feel and smooth appearance this sleeving is extremely tough and provides cables with both thermal protection and high abrasion resistance.

Electrical insulating tube sleeving add a layer of insulation to prevent electricity and heat from dissipating from wire and cable.

What s special about this fire resistant sleeving.

Application it is used in a wide range of applications.

Flexo nx nx formerly known as nomex sleeving will provide protection for wires hoses and cables that woven nomex clothing and protective gear used for years by race car drivers municipal fire departments and oil rig personnel to provide that etra level of comfort and protection from the dangers that come with working in and around intense flame and heat.

60 degrees c to 220 degrees c standards.

Insulates cables and hoses against temperatures up to 662 f 350 c helping them endure the brutal conditions of military aviation fire rescue and other applications that require superior flame resistance.

Jdd nm consists of 100 continuous nomex fiber.

There is a division running down the length of the middle allowing simple insertion and installation of wires and clusters of cables to take place.

A flexible tubular expandable cable sleeving braided with nomex polyaryl mide multifilament fibres.

Ht nomex high temperature expandable sleeving.

Exceptional thermal stability and chemical solvent and abrasion resistance.

Flexo nomex braided sleeving will do the same for your wires hoses and cables.

Nomex sleeving is manufactured from 100 continuous filament nomex fibers.

Mil c 572 type paa.

It can retain its integrity at temperatures over 245 c exposed to high humidity moisture or extreme temperature.

It won t irritate skin like fiberglass so it s easier to handle.

Flexo nomex braided sleeving will protect your application in temperatures up to 662 f.

Nomex is unaffected by exposure to most acids solvents and common engineering chemicals.

This sleeving has excellent tear resistance and better abrasion resistance than standard polyester sleeving.

The roundit 2000nx wrap around sleeving is going to be the ideal correspondence between both our expandable braided sleeving and split wire loom a k a.

Although its soft feel and smooth appearance this sleeving is extremely tough and provides cables with both thermal protection and high abrasion resistance.

Made of nomex fabric it resists most acids and alkalies alcohol hydraulic fluid oil gasoline salt water and solvents.

Made of nomex fabric this sleeving has excellent tear resistance and better abrasion resistance than nylon sleeving.

Can be cut with scissors.